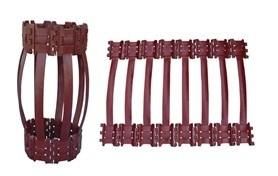

API Casing Centralizador

Puyang Zhongshi Group Co., Ltd.- Standard:API, ISO

- Usage:Well Drilling Machinery

- Material:65 Mn

- Type:Petroleum Drilling Tool & Accessory

- Tractor Hoist Type:Casing Centralizer

- Use:Horizontal Oil Well and Straight Wells

Base Info

- Model NO.:CC7

- Lead Time:15 Days After Order

- Sample Time:5 Days

- Size:4-1,2" to 20"

- Plate Thickness:3.8 Mm

- Surface Treatment:Electrostatic Painting

- Color:Red, Black, Orange or Others

- Transport Package:Standard Export Packaging, Wooden Case

- Specification:API 10D

- Trademark:PYZS

- Origin:China

- HS Code:73072900

- Production Capacity:50000 Set Per Month

Description

Basic Info.

Model NO. CC7 Lead Time 15 Days After Order Sample Time 5 Days Size 4-1/2" to 20" Plate Thickness 3.8 Mm Surface Treatment Electrostatic Painting Color Red, Black, Orange or Others Transport Package Standard Export Packaging, Wooden Case Specification API 10D Trademark PYZS Origin China HS Code 73072900 Production Capacity 50000 Set Per MonthProduct Description

1. Product Description

API casing centralizador is made of spring steel which has been heat teated and hardened tempered to ensure proper and consistent spring characteristics.

API casing centralizador. End collar hinges are folded toward inside. This way will minimize the collar stretch to occur when centralizers encounter tapers, commonly found in certain type of pipe connections.

A reinforcing rib stamped into the end collar.This way will strengthen and preserve it's round configuration during transport.Centralizers with built-in stop devices as well as those uncommon sizes are available based on request.

2. Functions of API casing centralizador

Let the casing pipe center on the well all the way.

Take casing to designed position by reducing sticking while casing going down.

Balance liquid pressure in annular space by reducing adhesion phenomenon.

Improving replacing ratio of mud and boosting cementing quality by reducing channeling effect.

3. Our Services

High Quality API 10D Integral Spring Casing Centralizer (7" Y 8-1/2"). Our products and services are closely related to oil drilling and oil well cementation. Our products include integral casing centralizer, welded casing centralizer, bow spring centralizer, float shoe, float collar, Suck Rod Pump, api pumping unit, Thread Protector, Thread Gauge, Api Valve Ball and Valve Seat, coupling and pump plungers.

4. Packing and Shipping of API casing centralizador

Wooden case, standard export packaging, firm enough for long distance sea-shipped, air transportation and even railway transportation.

5. Company Information

The predecessor of Puyang Zhongshi Group Co. Ltd, was the 5th Machine Repairing Factory of Puyang Zhongyuan Oil field, Sinopec Corp. In 1997, after being restructured according to the modern corporate system, the factory was named Puyang Zhongshi Group Co., Ltd.

With registered capital of USD 10.15 million, Puyang Zhongshi Group is composed of 9 subsidiaries, including 8 manufacturers and 1 trade company. Zhongshi Group covers an area of 200, 000 sq. M, including workshop area of 50, 000 sq. M. Various kinds of production equipment values USD 6.5 Million. It has a strong mechanical processing capability.

Our leading products are API casing centralizador, pumping unit, tubing pump & sucker rod pump, cementing accessories, down-hole tools, wellhead (X-mas tree), drilling solid control series, pressure vessel, camping house, air cannon, belt feeder and so on. They are mainly supplied to Central Asia, Southeast Asia, Africa and Middle East and many other countries.

Zhongshi Group has been the Tier One internet service provider of Sinopec. We passed ISO9001 quality management system certification and got approved to use API monograms on its oil machineries. So far, we have attained API 5CT, API 10D, API 11AX, API 11E and more are applying.

We would like to faithfully cooperate with friends from all circles with classic products and service to achieve common development.

| Model | ID (mm) | Thickness (mm) | Total Height (mm) | Max OD (mm) | Spring PCS | |

| 5 1/2 * 8 1/2 | 142-148 | 3.8 | 650 | 225 | 5 | |

| 6 * 8 1/2 | 154-158 | 3.8 | 650 | 225 | 5 | |

| 13-3/8 * 17-1/2 | 342-349 | 3.8 | 650 | 450 | 6 | |

| 20*26" | 510-518 | 3.8 | 650 | 670 | 10 |