API 7-1 Kelly Drill Pipe &Tool Joint &Nc 50 Drilling Pipe

Tianjin Tiancheng Import and Export Co., Ltd.- Standard:RoHS, BS, DIN, JIS, AISI, API

- Length:8.84-9.75m

- Usage:Oil Mining, Coal Mining, Well Drilling, Ore Mining

- Material:AISI4145h,4145h Alloy Steel

- Loading Port:Tianjin,Shanghai

- Drill Pipe:Welded Pipe

Base Info

- Model NO.:API 7-1 KELLY DRILL PIPE

- Outside Diameter:2-3,8", 2-7,8", 3-1,2", 4", 4.5", 5", 5.-1,2", 6",

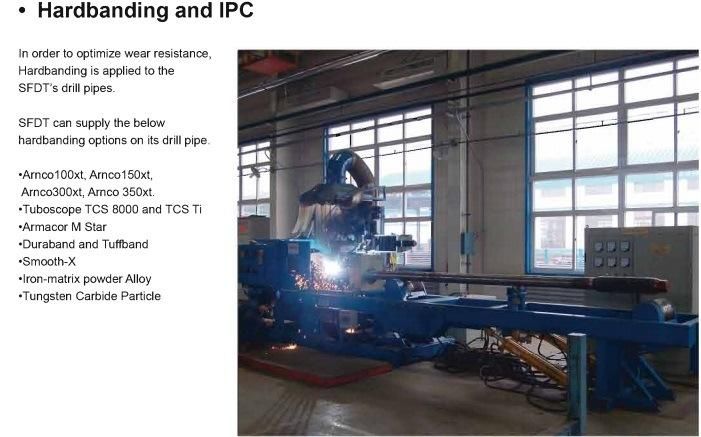

- Hard Banding:Arnco 100xt, Arnco 300xt, Tcs-Ti, Tcs-8000, etc.

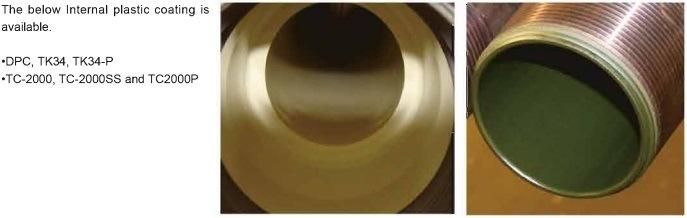

- Inner Plastic Coating: :Tc2000, Tc3000, Tk34, Tk34p

- Paiting:Black, Blue, or as Per Request

- Rh:Nc26,Nc31,Nc38,Nc50

- Lh:6-5,8 Reg

- Transport Package:Steel Case in Bundle

- Specification:OD2-1,2IN-6INCH

- Trademark:SFMC,TJTC,OEM

- Origin:Shanxi,Shandong,Jiangsu

- HS Code:7304231000

- Production Capacity:15000tons,Year

Description

Basic Info.

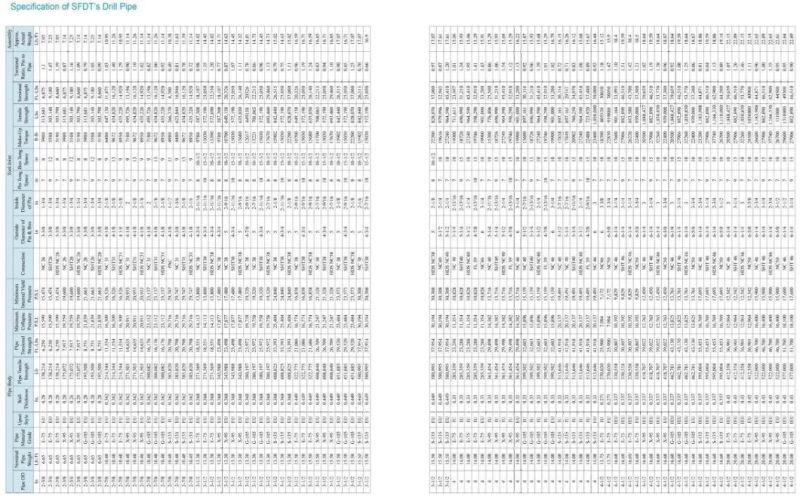

Model NO. API 7-1 KELLY DRILL PIPE Outside Diameter 2-3/8", 2-7/8", 3-1/2", 4", 4.5", 5", 5.-1/2", 6", Hard Banding Arnco 100xt, Arnco 300xt, Tcs-Ti, Tcs-8000, etc. Inner Plastic Coating: Tc2000, Tc3000, Tk34, Tk34p Paiting Black, Blue, or as Per Request Rh Nc26/Nc31/Nc38/Nc50 Lh 6-5/8 Reg Transport Package Steel Case in Bundle Specification OD2-1/2IN-6INCH Trademark SFMC/TJTC/OEM Origin Shanxi/Shandong/Jiangsu HS Code 7304231000 Production Capacity 15000tons/YearProduct Description

drill pipe are manufactured in according to or exceeds the requirement of API 5D, 7, and RP7G. The features are introduced as below:

1. The residual elements such as sulphur and phosphorus are strictly controlled in the pipe body and tool joints material during the steel making process, which makes the kind of material with high physical properties.

2. Heat Treatment is a decisive process in the production of tool joints and pipe body. Heat treatment must be uniform and deep enough to ensure required physical properties full length, especially in the critical sections of the connection and weld zone. Heat treatment programs are established on the basis of the actual chemical analysis of each heat of steel to ensure the materials meet or surpass the requirements of API Specification.

3. The drill pipe undergo a full-length inspection that checks the defects; especially the strict inspections on weldneck/upset region are preformed with our both manual and automatic inspection equipments to ensure the high quality.

4 The thread is the most important factor for drill pipes. All threads would be machined with CNC Lathes and inspected with related thread gauges in conformance with API Specification. All threads would be phosphated or copperized and the roots are cold rolled to improve the resistance of galling during initial break-in and drilling operation. Upon the customer's request, The Break-in process is conduced to economize the rig handling time. All Connections would be equipped with pressed steel or plastics steel thread protectors.

Besides SFMC's logo, API monogram, serial number of the finished drill pipe and tool joints and size of the connections are painted or stamped according to the requirements of API specification

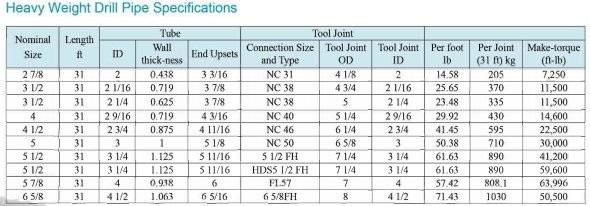

Model NO.: heavy weight drill pipe

Tool Joint Materials: 40cr, 45mn2, 35CrMo, 4137h

Application: Well Drilling

Inner Plastic Coating: Tc2000, Tc3000, Tk34, Tk34p

Paiting: Black, Blue, or as Per Request.

Upset: Iu, EU, Ieu,etc

Specification: API, ISO, GOST

HS Code: 7304231000

Pipe Body Material: E75, X95, G105, S135, R780

Length: R1, R2, R3

Outside Diameter: 2-3/8", 2-7/8", 3-1/2", 4", 4.5", 5", 5.-1/2", 6",

Hard Banding: Arnco 100xt, Arnco 300xt, Tcs-Ti, Tcs-8000, etc.

Thread Treatment: Phosphorization, Copper Plating, etc.

Origin: China

Heavy Weight Drill Pipe (HWDP) was developed to provide a gradual transition from the drill collars to the drill pipe. This HWDP helps to prevent stress concentration at the top of the drill collar.It also allow drilling at higher rpms, reducing torque and differential pressure sticking. The HWDP is intended primarily for directional drilling. As it bends easily, it simplifies directional control and minimizes connection fatigue problems common to high-angle or horizontal drilling. The reduced number of pipe failures and increased drill-stem service also make HWDP appropriate for some straight-hole applications. Various combinations of HWDP, drill collars, and standard drill string can be created to meet the challenge of severe drilling conditions.

SFMC can supply integral HWDP from 2-7/8" to 6-5/8". Also SFMC can supply friction welded HWDP, which is assembled with AISI 1340 steel pipe and AISI 4145H or 4137H tool joints.