Wear Resisting Tungsten Carbide Rotary File

Zhu Zhou Evergreen Hardmetal Tools Co., Ltd.- Standard:ISO9001

- Length:Taper-length

Base Info

- Model NO.:Wear Resisting Tungsten Carbide Rotary File

- Type:Twist Drill Bit

- Material:Tungsten Carbide

- Usage:Wood Drilling, Well Drilling, Metal Drilling

- Teeth Type:Fine Teeth, Rough Teeth, Medium Teeth

- Transport Package:Plastic Pipe Per Piece

- Specification:tungsten carbide and steel

- Trademark:Evergreen or OEM

- Origin:China

- HS Code:8466910000

- Production Capacity:3 Tons, Month

- Package size per unit product:20.00cm * 15.00cm * 10.00cm

- Gross weight per unit product:1.000kg

Description

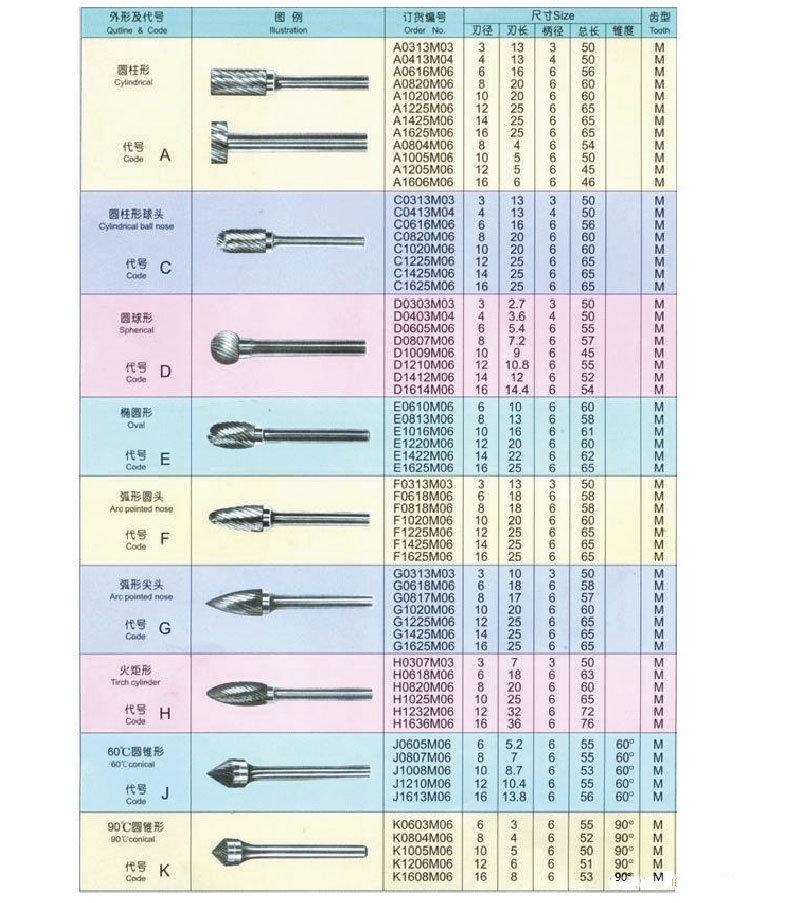

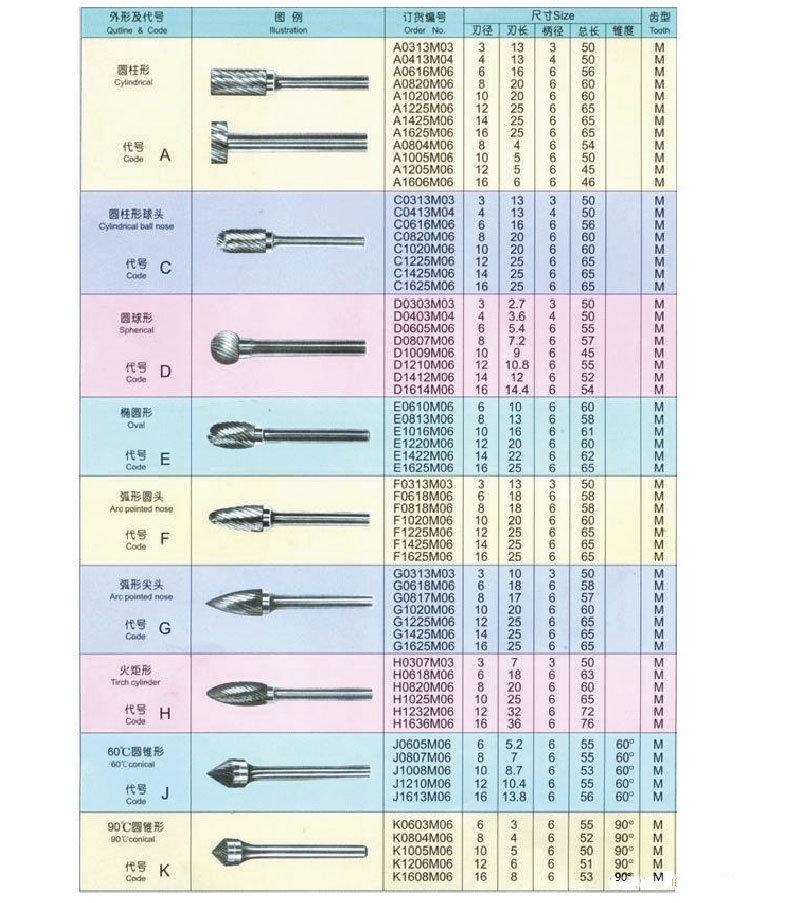

Grain SizeHRA HV10: K10 6.0±0.2 14.85~15.01 90.5~91.2 1450~1520 2000 fine K20 8.0±0.2 14.64~14.80 89.7~90.5 1370~1450 2200 fine

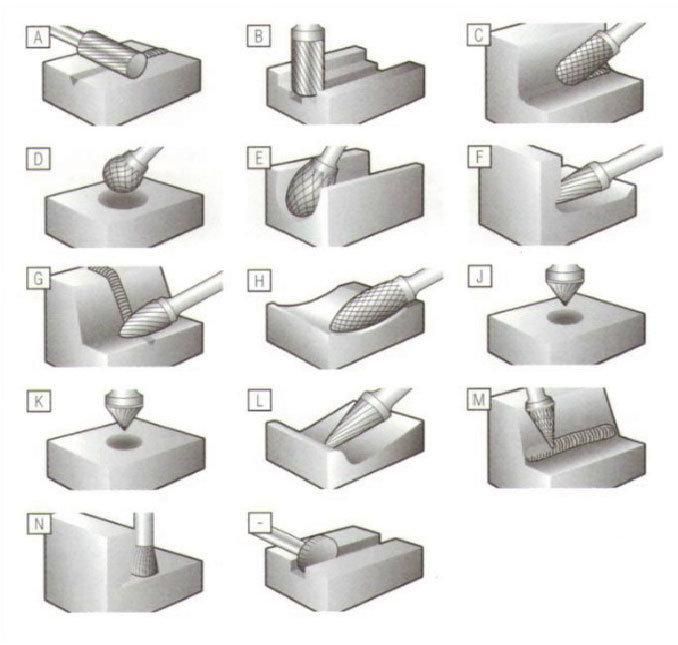

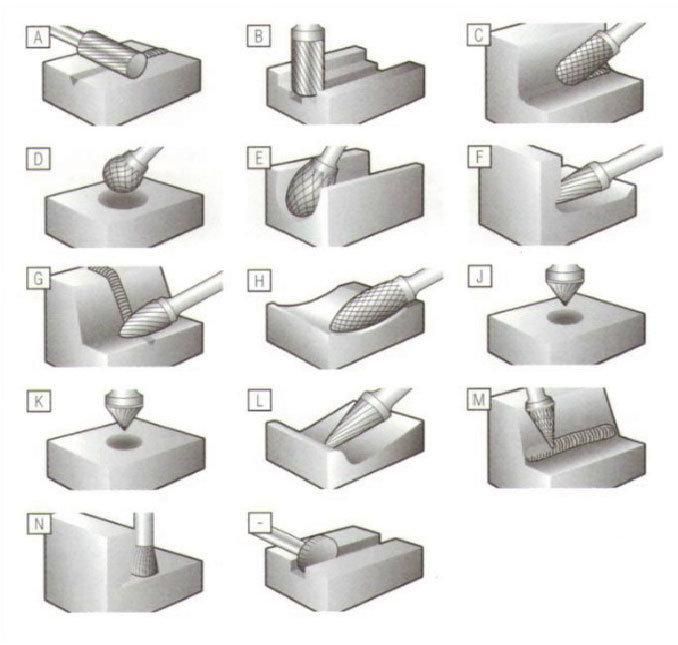

Shape descriptionCylindrical, Cylindrical ball nose, Spherical, Oval, Arc round nose, Arc pointed nose, Torch-shaped, Conical,Taper with round top, Conical pointed nose, Inverted conical, Cone flat nose, Dise type with arc edge,Concace arc shape, Cplimni form with half round nose, Dise type of 90 degree.

Shape descriptionCylindrical, Cylindrical ball nose, Spherical, Oval, Arc round nose, Arc pointed nose, Torch-shaped, Conical,Taper with round top, Conical pointed nose, Inverted conical, Cone flat nose, Dise type with arc edge,Concace arc shape, Cplimni form with half round nose, Dise type of 90 degree.

Dimension

Features of tungsten carbide rotary burrs:

1. All burrs are 100% braze tested for strength and safety

2.. All burrs are silver brazing

3.Tungsten carbide Burr ranges through ANSI Standard and DIN Standard and has different carbide grades suitable for different purposes.

Applications:

tungsten Carbide Rotary Burr is an effective way to realize mechanization in hand work operations. In the fields of airplane, ship building, automobile, machinery, chemistry etc., carbide rotary Burr can be widely used in machining iron, steel casting, carbon steel, alloy steel, stainless steel and copper aluminum etc.

1, Used for finishing the surfaces of metal and non-metal

2, Removing the burrs of casting, forging and the welding spatter on the weld assemblies

3, Chamfering angle, circular bead or flute on the mechanical parts

4, Chamfering or burring the pipes.

5, Polishing the impeller channel

6, Grinding the hole for accurate shape

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Contact way;

Shirley

Mobile/+86-19973330313

Shape descriptionCylindrical, Cylindrical ball nose, Spherical, Oval, Arc round nose, Arc pointed nose, Torch-shaped, Conical,Taper with round top, Conical pointed nose, Inverted conical, Cone flat nose, Dise type with arc edge,Concace arc shape, Cplimni form with half round nose, Dise type of 90 degree.

Shape descriptionCylindrical, Cylindrical ball nose, Spherical, Oval, Arc round nose, Arc pointed nose, Torch-shaped, Conical,Taper with round top, Conical pointed nose, Inverted conical, Cone flat nose, Dise type with arc edge,Concace arc shape, Cplimni form with half round nose, Dise type of 90 degree.Dimension

Features of tungsten carbide rotary burrs:

1. All burrs are 100% braze tested for strength and safety

2.. All burrs are silver brazing

3.Tungsten carbide Burr ranges through ANSI Standard and DIN Standard and has different carbide grades suitable for different purposes.

Applications:

tungsten Carbide Rotary Burr is an effective way to realize mechanization in hand work operations. In the fields of airplane, ship building, automobile, machinery, chemistry etc., carbide rotary Burr can be widely used in machining iron, steel casting, carbon steel, alloy steel, stainless steel and copper aluminum etc.

1, Used for finishing the surfaces of metal and non-metal

2, Removing the burrs of casting, forging and the welding spatter on the weld assemblies

3, Chamfering angle, circular bead or flute on the mechanical parts

4, Chamfering or burring the pipes.

5, Polishing the impeller channel

6, Grinding the hole for accurate shape

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Contact way;

Shirley

Mobile/+86-19973330313