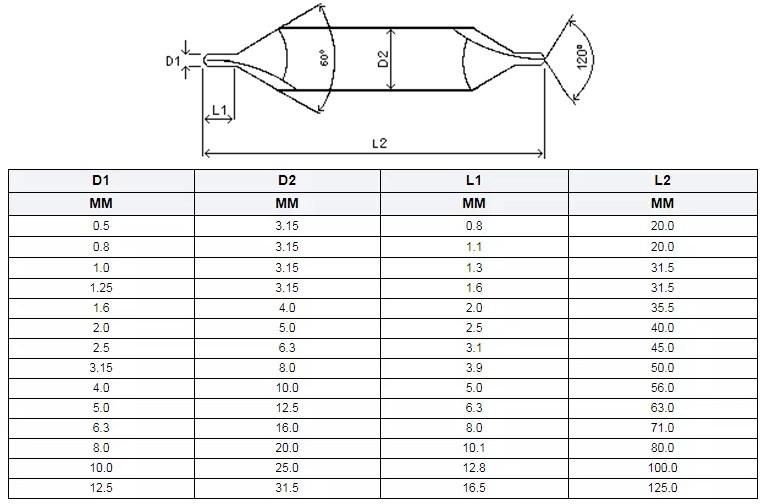

DIN333 Tin-Coated HSS Spot Center Drills for Centre Drilling (SED-SCD-T)

SHANGHAI EASYDRILL INDUSTRIAL CO., LTD.- Customized:Customized

- Standard:DIN

- Length:Jobber-length

- Type:Center Drill Bit

- Material:High Speed Steel

- Usage:Metal Drilling

Base Info

- Model NO.:SED-SCD-T

- Dia Size:1mm-20mm

- Production Art:Fully Ground or Forged

- Min Quantity:100PCS

- Packaging:PVC Bag,Setcase,Plastic Box,Metal Box

- Surface Finish:Tincoated

- Transport Package:PVC Bag, Blister Card, Plastic Box, Metal Box etc

- Specification:ISO9001, SGS, CE

- Trademark:EASYDRILL

- Origin:China

- HS Code:820750900

- Production Capacity:200, 000PCS,Month

Description

Straight Flutes(2 Flute is Available)

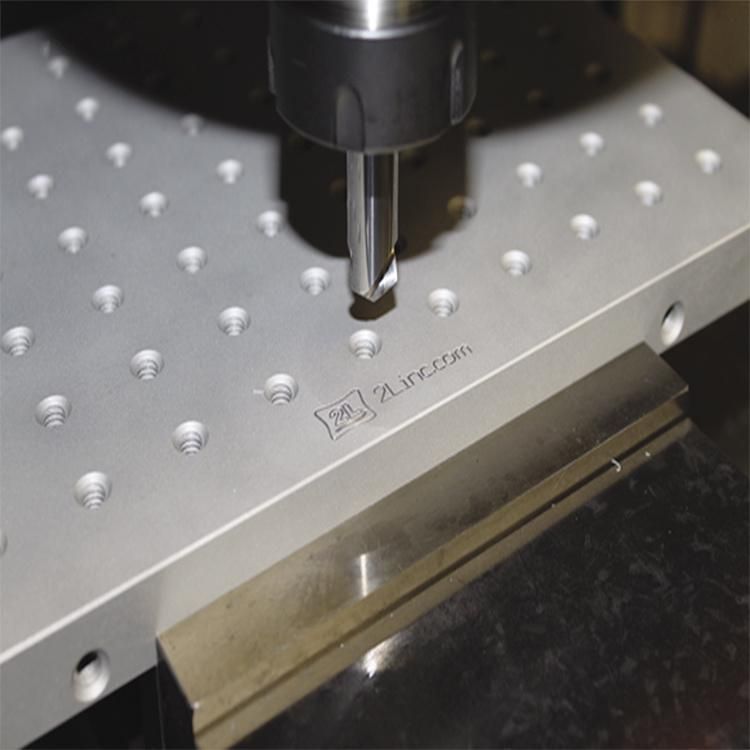

1.Center drill bits can be used to make conical holes for a lathe center in order to make a starting point for a standard twist drill, designed to prevent the twist drill from walking, as well as for producing center holds in components or work pieces with require machining between centers.

2.Available for all Kinds of Materials: Metal, Alloy, Copper, Iron, Wood, Aluminum, and so on.

3.Durable and Resistance: Center drill bit is made of HSS high speed steel, with extremely sharp blade, low consumption and durable with impact resistance, wear resistance.

4.center drills have flutes and cutting points on both ends. this allows the user with the ability to reverse the drill and utilize both ends.

5.Titanium-Coated High-Speed Steel for maximum durability and lasts up to 6X more than conventional bits. Titanium Coating acts to enhance the surface hardness of the drill to improve accuracy and reduce friction when drilling and also helps to control the temperature and wear resistance so as to increase efficiency

6.60 degree countersink angle fits all standard centers

7.High-speed steel tools are good for most general purpose applications, offering a combination of hardness and toughness for wear resistance