PPR /HDPE Drill Bit for Saddle Bush

Hangzhou Fuyi Tools Co., Ltd.- Customized:Customized

- Standard:DIN

- Length:20mm-110mm

- Type:Drill Bit for Weld in Saddle

- Material:High Speed Steel

- Usage:Plastic Pipe

Base Info

- Model NO.:FYKJ

- Drill Bit Material:Iron

- Drill Material:High Speed Steel

- 20mm Drill Bit:for 20mm PPR Pipes

- 25mm Drill Bit:for 25mm PPR Pipes

- 32mm Drill Bit:for 32mm PPR Pipes

- 40mm Drill Bit:for 40mm PPR Pipes

- 50mm Drill Bit:for 50mm PPR Pipes

- 63mm Drill Bit:for 63mm PPR Pipes

- 75mm Drill Bit:for 75mm PPR Pipes

- 90mm Hole Saw:for 90mm PPR Pipes

- 110mm Hole Saw:for 110mm PPR Pipes

- Hole Saw Color:Black

- Package:Plastic Box

- Tool:Electric Drill

- Popular Size:20mm -63mm

- Transport Package:Carton

- Specification:20mm -110mm

- Trademark:OEM , FUYI

- Origin:China

- HS Code:8515900090

- Production Capacity:300, 000PCS,Year

Description

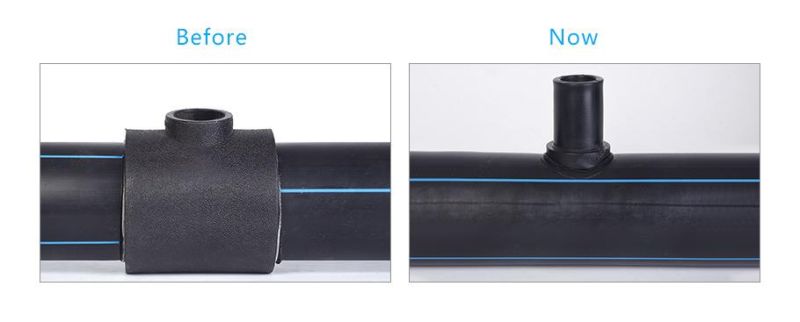

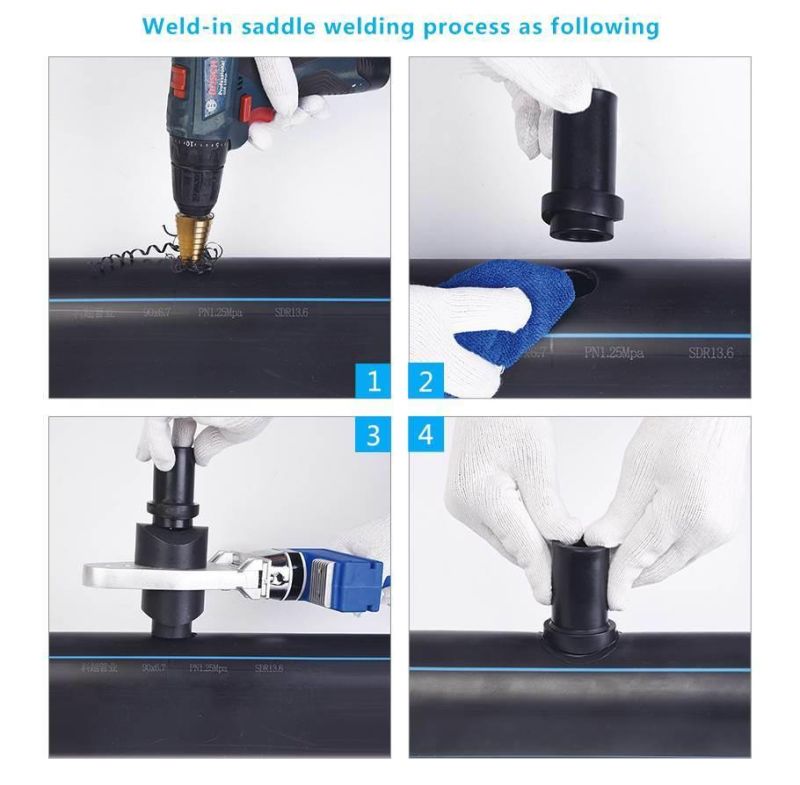

Weld-insaddle welding process as following:

1.Drilla hole though the pipe wall with the drill. Pay more attention on the depth ofthe drill.

2.Clean the hole with the piece of fabric or napkin. The welding surfaces have to beclean and dry. For stabi composite pipes remove the rest of the aluminumremaining at the drilled hole by chamfering the edge of the hole.

3.Once the socket welder is on, wait until the machine indicates the reaching of theworking temperature (260°±2°). Push the saddle heating tool with the spigotinto the pipe hole and the saddle into the other tool. Heat the pipe surfaceand the saddle for 30 seconds.

4.Once the hating process is over remove the socket welder ad push the saddles spigotinto the pipe hole with a light pressure until the surface meet entirely. Keeppressing for about 15-20 seconds. Let the joint cool down for 20 minutes beforemaking the pressure test.